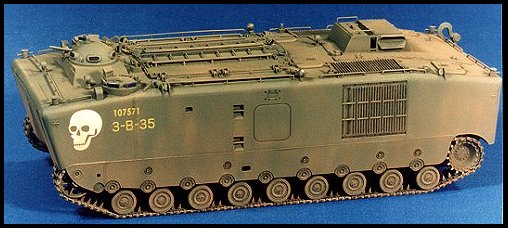

AFV Club AF35022 LVTP5A1 Landing Vehicle Tracked Personnel

Terry Ashley

I have just received this advance release of the new LVTP5A1, courtesy of the

Australian AFV Club distributors

JB Wholesalers. The kit consists of 260 parts in olive drab plastic, plus a further

68 parts for the tracks. The tracks are 'link and length', which I prefer over the full

individual links in some kits and aftermarket sets. Especially for this kit, where the

hull sides hide the track tops. The quality of the mouldings is excellent,

with many of the parts being extremely small and finely moulded. Extreme care must be

taken when removing these bits from the sprues. The quality of the mouldings is well up to

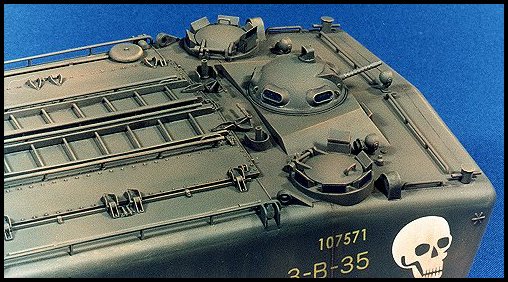

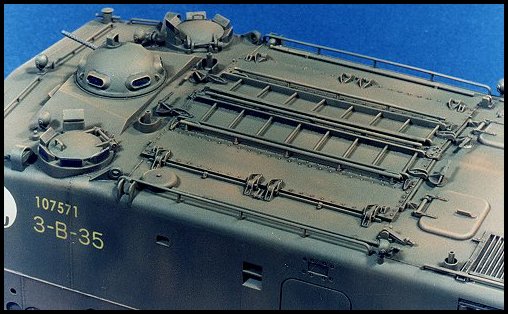

the standards of the earlier AFV Club releases. The hull top is in one piece measuring

250mm (10") in length with cutouts for all hatches and engine compartment. The

surface detail is very well done, especially the weld seams along the top edges and on the

front plate/hatch and along the hull sides.  While there is no interior included in the kit, there is detail on the inside

of the forward hull and side escape hatches. Maybe the rumours of Hobby Fan (parent

company of AFV Club), releasing a resin interior for this kit have some merit. The large

top hull troop hatches are in four separate pieces and designed to operate with small,

well done hinge mechanisms. The other smaller top hatches are also separate pieces. All

this adds weight to an interior coming along later.

While there is no interior included in the kit, there is detail on the inside

of the forward hull and side escape hatches. Maybe the rumours of Hobby Fan (parent

company of AFV Club), releasing a resin interior for this kit have some merit. The large

top hull troop hatches are in four separate pieces and designed to operate with small,

well done hinge mechanisms. The other smaller top hatches are also separate pieces. All

this adds weight to an interior coming along later.

Construction

This review kit is built straight out of the box, to give an account of basic

construction and identify any traps along the way. As with any kit there is

potential to detail the kit further.

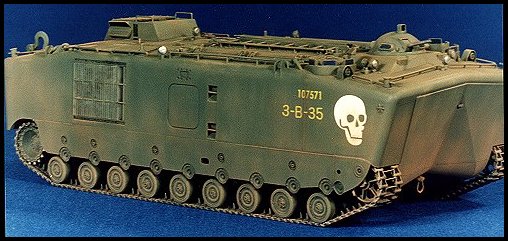

Construction begins with the running gear. With 8 bogie assemblies of 4 parts on each

side, this is a slightly tedious undertaking, but construction is straightforward. The

drive sprockets, idler wheels and road wheels have good surface detail. The only problem

encountered was the locating points for the bogies being a little "sloppy"

requiring care to get all the road wheels aligned level with the ground. The bogie

assemblies and idler wheels are then trapped between the main hull and the side panels.

The fit is good with precise locating points between the hull and side panels. The rear

and front hull panels are then

added to form the basic "box" hull. It is important to use tape to pull the

panels together as the glue dries, thus eliminated any

need for filler. The join lines coincide with weld seams on the hull front and rear, a

nice design feature by AFV Club. The front boarding ramp has detail on the inside and the

hinges are designed to work, another indication that some sort of interior may follow.

I deviated from the instructions in leaving the drive sprockets and track off at

this stage, to be added later. (see below)

The instructions also call for the large number of small detail bits to be added to the

top hull before attaching this to the lower hull, this leaves a lot of scope for damaging

these small parts when attaching the top hull. For this reason I attached the hull top to

the main body at this point. The fit of the top hull is good, but tape must be used to

"pull" the joins together to ensure a fit not requiring filler. There is

potential for Grand Canyon type gaps if care is not taken attaching the hull top. After

the glue had dried I cleaned up the hull top/side join line with fine wet and dry paper.

No filler was required.

This completes the basic construction, you now have basically a big box on tracks. I

glued all the separate hatches in the closed position, as there was no interior to be

shown off.

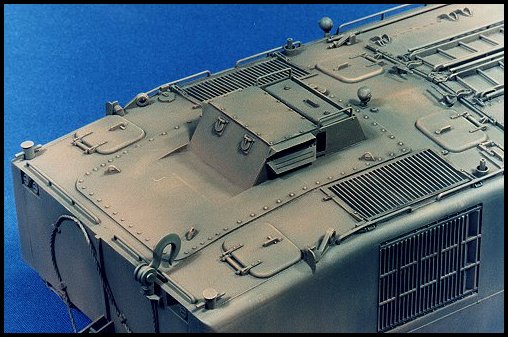

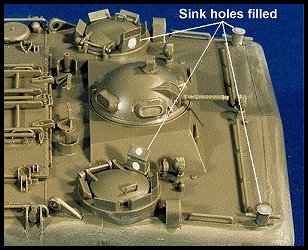

The other two main 'sub assemblies' are the turret and engine exhaust "box". The

turret fitted together without any problems, the five periscopes are separate pieces and

give good definition. I also drilled out the .30cal barrel. There are some very small bits

to be added to the turret, a pair of good quality tweezers is essential. The exhaust box

was added to the separate top panel. The fit here again was spot on with no filler

required. This assembly is then fitted into the hull top cutout. The fit was again

excellent with it almost holding in place without glue, I did of course glue it on. The

two engine grill panels either side if this assembly also fitted precisely.

There is a myriad of small detail bits, fine grab handles and spot lights etc. to be added

to the top hull. I won't go over each bit separately, only to say that careful removal

from the sprues and cleaning up of the parts (mould lines etc) is required. I found it

easier to remove the fine mould line along the grab handles before removing them from the

sprues. The only area requiring attention here was the two large periscopes on the crew

cupolas. They are separate pieces and had mean sink marks, which required filling,

the tops of the four mooring posts had small sink marks requiring filler. A couple of the

searchlights also had small sink marks in the center of the lenses, but apart from this

there were no other imperfections in my sample. Fitting of all these fine bits is

fairly time consuming, but don't cut corners as this will show in the final appearance of

the kit.

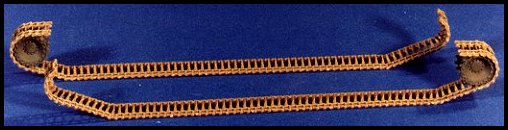

The tracks: As mentioned these are in link and length style. I didn't add the track hidden

by the hull over the return rollers, for ease of assembly and as it's basically a waste of

time. I left the drive sprocket off to allow for the fitting of the tracks. The

separate track links are laid around the drive sprocket and lightly glued with liquid

cement (taking care not to glue them to the sprockets themselves). Once this section had

dried, I attached the length sections in turn (with a separate link for the bend around

the end road wheels) and finally the separate links around the front idler wheel. This was

repeated for both sides and you are then left with the track assemblies (see pic). A final

application of liquid cement was brushed on the ensue all the joints were secure. When

dry, the tracks can be removed from the drive sprocket and painted separately. The tracks

were finally attached to the model prior to final weathering.

Decal/Painting/Weathering

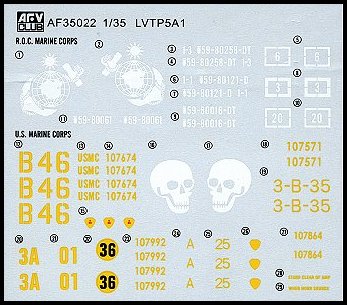

The decal sheet provides markings for 3 USMC vehicles as used in Vietnam and 2 vehicles

of the ROC Marines. A nice touch to the painting guide is paint numbers given for Tamiya,

Gunze, Humbrol and Revell paints.

The kit was given an overall coat of Humbrol HP5 "U.S. Marine Corps Green". When

dry, I glossed the areas for the decals. The decals are good quality and very thin, only a

small amount of decal setting solution was needed for a good "sit" on the model.

When dry, the model was given an overall coat of matt varnish. Weathering was

applied using a combination of black washes, dry brushing and light over spray of dust

etc. I kept the weathering to a minimum to allow the kit details to be seen.

This is an excellent kit with good detail and will build into an impressive

"bus". The amount of small details included in the kit is most impressive. The

only real omission was an interior. With such a large front loading ramp and top hatches

this would be easily seen. Maybe AFV Club will release another version of the kit with

interior (at a higher price obviously) like Tamiya did with their original M113's?

Conclusion

As with any kit there is room for added detailing. Some of the hatch handles could be

replaced and other small bits refined. I

my opinion the many grab handles around the hull top do not need replacing with wire as is

often the case with over scale bits. These parts in the kit are nice and fine and

look just right when fitted.

In all an excellent kit, highly recommended for U.S. armour buffs. The fit of the parts

was excellent and as mentioned the level of detail impressive. It will look great with a

herd of grunts sitting on top enjoying the view. This is a "big" vehicle.

Review graciously provided by Terry Ashley: Perth

Military Modelling Society

| Main | What's New | Articles | Reviews | Gallery | Think Tank | Contests |