| |

BrassAssist Roller Set Mk ‘MC’

by John Prigent

I received the new BrassAssist from The Small Shop EU to use for a projected

modelling book, and it has proved very useful indeed.

It is a neat tool for rolling rounded shapes in etched metal parts –

and it should work just as well on items cut from the brass or copper

sheets and strips that can be found in good hobby shops. I haven’t

tried it on aluminium so can’t offer advice there.

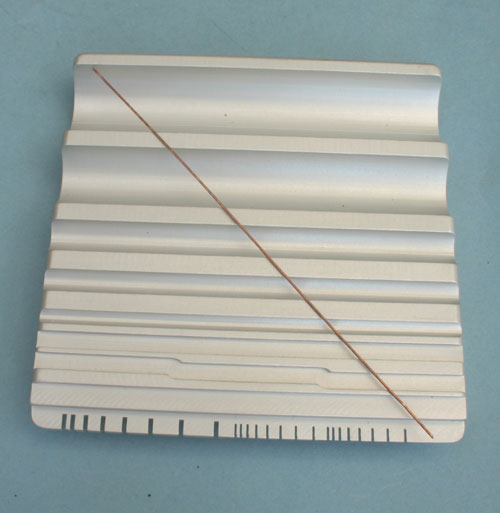

The tool base is a 10 cm (4 inches) square block of aluminium, 1.5 cm

(5/8 inch) thick so the whole thing is quite solid and stable in use.

Into it recesses have been milled to take the rollers, each a perfect

half-circle. The rollers come in five sizes to produce diameters of 2

cm (25/32 inch), 1.6 cm (10/16 inch), 0.8 cm (5/16 inch), 0.5 cm (7/32

inch) and 0.3 cm (1/8 inch). They are solid metal, aluminium for the two

largest, brass for the next two and steel for the smallest so there’s

no risk of bending them. As well as the roller recesses there are milled

ribs to allow easy shaping of etched tie-downs in three different lengths

and two alternative depths. On the front edge of the piece are milled

slots for bending wire to make grab handles; these give four different

widths, each catering for three different wire thicknesses and three different

depths of handle bend if you need to turn out the bottoms of the handles

to represent the type that isn’t butt-welded. And to top it, since

the spacing of the slots is staggered you can use them to produce almost

any size of grab handle from 1 mm up to 6.5 mm inside length – outside

lengths from 3 m to 9.5 mm in the thickest rod, 1 mm diameter, or 2 mm

to 5 mm in the thinnest, 0.5 mm. The whole top surface is engineered to

provide a stable flat surface so you can turn it over to use the second

feature – a soft rolling surface 8 cm (3 1/8 inch) square.

So how does it all work? Very well, actually. You do need to anneal

the etched part before using the rollers, by heating it red hot and letting

it cool. Then simply place it over the appropriate roller recess and press

the roller down into it. This will give you an perfect arched shape, but

if you want a complete cylinder you can turn the base over and use the

next smallest roller with the soft surface to roll the part back and forward

until the cylinder is complete. It is of course important to make sure

the part is at a right angle to the roller recess before you start, if

its angled you’ll end up with the two ends not matching! Although

I haven’t experimented it does appear that rotating the part in

its roller recess and re-applying the roller will allow you to form parts

with more than a half-circle, and might even allow you to make a complete

cylinder without rolling it on the back of the tool. The rolling surface

can of course be used to form cylinders or partial cylinders that don’t

correspond to any of the roller recesses, just use whichever roller suits

and roll the part till you get the larger or smaller curve you need.

The tie-down ribs work equally well, but again the part must be at a

right angle to the rib before you start. I tested the grab handle slots

with both brass and copper wire and found that brass did not shape very

well. The instructions do point out that only soft wire works! It’s

quite easy to bend copper wire (I take it from various sizes of electric

cable bought in 1 metre lengths from a hardware or electrical accessory

shop) into an arc and pop it into the slot you want, then pull down on

both ends with pliers till the top is almost flat and press it completely

flat with the back of the pliers. Then either cut off the ends or, if

you need the non-butt-welded type, turn out the ends and cut them to a

suitable stub. Take out the new handle and flatten the stubs with your

pliers and its ready to fix to the model. Although I managed easily without

doing so, annealing the thicker sizes of wire might make the job easier

still.

There is one thing I should mention: keep your work surface clean while

you use this tool. The soft rolling surface will pick up bits of plastic

shavings, the stubs trimmed from etched parts, etcetera, and these will

spoil the nice soft surface when you try to roll parts on it. The Small

Shop EU does sell replacement rolling surfaces if you ever need one!

Many thanks to them for supplying the BrassAssist. Their website is

at www.smallshopeu.com.

|

|