Home >

Gallery >

Britain > Building a Full Resin

Resicast Sherman ARV Mk.I

Part One - Construction |

|

Building a

Full Resin Resicast Sherman ARV Mk.I

Part One - Construction |

Resicast,

1/35 scale |

|

by Paul Chatfield

|

Resicast's 1/35 scale Sherman ARV Mk.I is available online from Mission Models

Introduction

With the ever-increasing amount of resin conversion kits and some

really nice full resin kits becoming available, I thought I would

offer some suggestions, based on my own experiences, on building a

resin kit.

Manufacturers such as Resicast, Accurate Armour, Plusmodel and

Cromwell models all now offer full resin kits of a nice range of AFV

subjects. Very often these subjects are unavailable in traditional

injection moulded plastic kits.

For this article I’m going to be using Resicast’s Sherman ARV MkI

full resin and photo etched Brass (PE) kit. Resicast also offer this

vehicle as a conversion kit, for the Dragon Sherman, which is

considerably cheaper than this full kit, but does require the

purchase of the Dragon base kit too.

Pros

and Cons of Resin Kits Pros

and Cons of Resin Kits

Resin kits are not for everyone

and have their advantages and disadvantages. I’ll now try and give

an honest list of the pros and cons of resin kits.

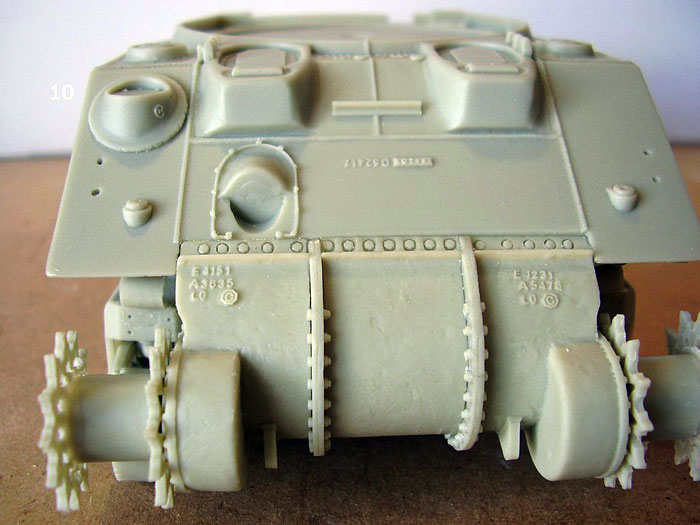

To begin with the advantages of resin; Surface detail is usually

much finer than an injection kit. For example on the Resicast

Sherman; weld seams are correctly shown raised, foundry casting

numbers are visible all over the model, the surface has a definite

cast texture and detail is cast on both sides of parts. Resin can be

used to cast much finer parts than injection moulding and some of

the detail is stunning. Due to the different technology used resin

parts carry no ejector pin marks so there are none to fill or sand

off. Being limited run, most kits offer a significant advantage in

accuracy over mass produced kits. This also means the purchase of

aftermarket correction or detail kits is rarely necessary. (I have

never bought after market tracks for a resin tank) Resin

manufacturers tend to do kits of less mainstream subjects, so you

get some really different and interesting subjects.

Now the disadvantages of resin kits; Firstly for most people cost.

On the whole, resin kits cost more than injection kits, sometimes a

lot more. This can be balanced somewhat by the fact that you don’t

need to buy aftermarket parts. Resin requires different tools. You

will need Razor saws for separating parts from pour stubs and super

(crazy) glues for attaching parts. You may also require 2 part epoxy

glues in some cases. You will need dust masks and extractors when

sanding or sawing resin. (But you should already have an extractor

in your paint booth). Some parts can suffer from air bubbles that

need filling and sanding. Fine flash may require clean up on smaller

parts. Some parts can warp or distort, although dipping in warm

water and straightening will easily remedy this. The instruction

sheets from some manufactures leave a lot to be desired and the

modeller often needs to use references to find the correct location

of parts.

Building the Sherman ARV

Building Shermans can be a bit

confusing, due to the large range of variations and modifications

built throughout its operational life. Resicast do an excellent

range of resin Shermans of different types such as M4A4, M4A1,

Direct vision hull, Duplex drive as well as the ARV. Luckily

Resicast have done their Sherman research thoroughly and you can be

pretty certain that all parts are where they should be for the

particular type of Sherman you are building.

On opening the box you are faced

with a mass of parts; large resin mouldings for the hull, bags and

bags of smaller detail resin parts, Resin tracks, PE frets, plastic

rod, string, copper wire and little lenses, along with an

“instruction” booklet.

Lower Hull and Tracks

As with most armour kits construction starts with the lower hull and

suspension. The detail on the Resicast parts is superb. Most of the

lower hull is one large casting. It carries not only the external

details but also details on the interior surfaces. (Resicast offer

another separate kit to fit out the inside of the M4A4) The lower

front hull containing the transmission is cast as a block, again

with all interior details shown.

The road wheels and suspension

need separating from their casting blocks with a razor saw and

some “webbing” cleaned out of hollow areas. I used a sharp Swann

Morton No 11 blade to clean out these areas, and then sanded them

smooth. Each set of wheels and suspension requires only three parts;

wheels mounted in swing arms, main suspension body and the top track

guide. . Once tidied up and assembled detail is superb, the wheels

click into place without the need for gluing.

Click the thumbnails below to view additional images:

With all the road wheels made up I

attached them to the hull sides, taking note, which sets fitted to

which side. This being a limited run resin kit, instructions aren’t

laid out in a step-by-step system, as you would expect with Dragon,

Tamiya, Italeri Etc. The instructions consist of a (long) list of

parts and numbers and a series of photocopied photographs of a model

during construction. This means the modeller has to study the photos

carefully for parts positioning. A good photo reference of an actual

vehicle is also very helpful. To add complication, on this

particular kit, some part numbers/letters are duplicated due to the

fact that this kit is a combination of Resicast’s complete M4A4 kit

and a conversion kit (to ARV spec) that also fits Dragon’s Sherman.

With the wheels on the Hull it became obvious that the lower hull

was a little warped. The left rear road wheels didn’t touch the

ground at all! With resin, this is not that hard to remedy. I took a

bowl of hot (not boiling) water and submerged the whole model in it

for 3-4 minutes. Then placing model on a firm flat surface I placed

a heavy object (in this case a piece of Granite slab I had hanging

around) on the wheels to push them into line. I left this for around

30-40 minutes to cool and set back in place. Once the Granite was

removed the model was stood back on it’s wheels and every thing now

touched down as it should. (Still dripping!).

Click the thumbnails below to view additional images:

Next to be attached were the rear

engine plates and doors. Attached to these are the rear idlers,

which complete the build of the running gear. The entire top hull is

one casting. To make this fit a little bit of “tweaking” was

required. The left hand sponson bottom just refused to sit in its

channel, under the sponson. I marked the area, which was a problem

and sanded it back until a good fit was achieved. Constant checking

is needed here to make sure you don’t take too much away. With this

done the upper hull slipped into place easily and the fit around the

front, to the transmission block is virtually perfect and something

even the very best mass-produced kits would struggle to equal.

The final part of the lower hull

construction was the tracks. On most injection kits I would buy

aftermarket tracks, usually individual metal links that take an age

to build. With this kit I didn’t have to bother, because Resicast

provide very nice resin tracks. The tracks are provided in several

different lengths of links. The night before I needed them I made up

two lengths of track, one for each side. Each length was enough to

cover the top run and tuck underneath the road wheels at the front

and the back.

With the tracks totally set they

were placed over the upper part of the running gear, with a good

over hang at the front and the back. Now for a very unusual

modelling tool, a hair dryer! With the tracks in position a hair

dryer, set to hot, was aimed at the over hanging portions. Within a

few seconds they started to droop. When they were fully “sagged” the

tracks were fitted around the front sprocket and the rear idler

wheel, then the model placed flat on the workbench. After a couple

of minutes the tracks had cooled and set into their new shape. Care

should be taken with the hair dryer as it softens all resin that it

comes into contact with and delicate parts can easily warp. With

everything cooled and set, adding more links between the ends of the

fitted track finished off the tracks. They were not completely

joined, as the tracks will be taken off of the model for painting,

the final join can be done when all painting is finished.

This method of track building is

so much quicker than individual links and is well suited to the

tight “live” tracks fitted to Shermans. I’ve never used a resin

replacement set on tracks with droop, like Panzers or T-34s, and I’m

not sure how well it would work with them.

Click the thumbnails below to view additional images:

Upper Hull and Fittings

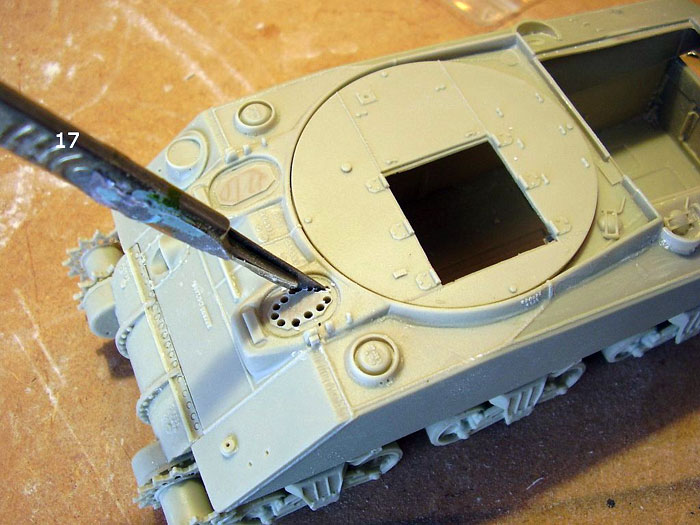

The upper Hull, as mentioned previously, is one solid casting. This

means the holes for the engine deck covers, the turret plug and the

driver hatches need cutting out. Before I started cutting I marked

out the areas I needed to remove. To cut out the main parts of the

bigger holes I used a Dremmel motor tool fitted with a cutting disc.

This is a VERY dusty process and an extractor and dust mask are a

must, as is eye protection. I cut the holes slightly smaller than I

required and finished them with files and sanding sticks. For the

smaller crew hatches I used a different much less dusty technique. I

drilled out a series of holes inside the line of what I needed to

remove then cut through them with a sharp blade.

Click the thumbnails below to view additional images:

The hole was then trimmed almost

to size with the blade, and then the last little bit was done with a

small file.

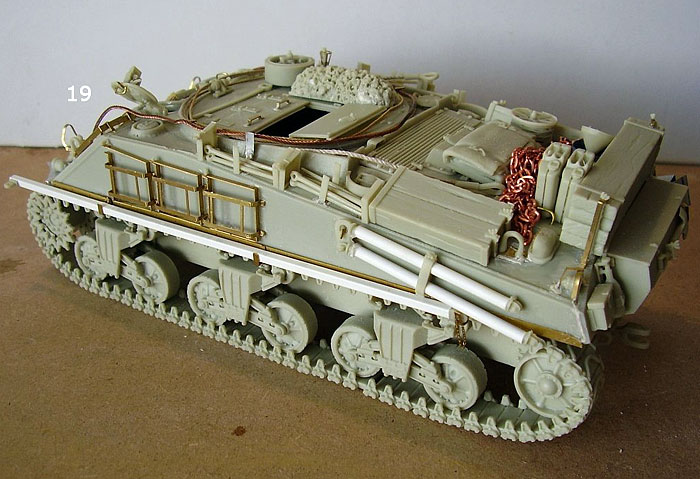

Now it was time to start fitting the multitude of hull fittings that

the ARV featured. I started with the “standard” fittings, lights,

lifting hooks, intakes and the like. After this came the specialised

fittings of the ARV. There are literally dozens of parts to be

fitted and the instructions are not that clear as to the exact

placement and positions of some parts. This is where good reference

photographs really help. I have a photo of an actual ARV in the

field that I want to base this model on, so some parts were placed

with reference to what I could see in the picture and not what’s in

the instruction booklet anyway. As with most resin kits there are no

tabs or holes for fitment of the parts they are simply glued to the

hull.

The majority of fittings are in resin with just a few brackets and

support frames in PE. I won’t bore you with a long list of parts

fitted or the order in which I fitted them. All I will say is, on

this model, it takes a long time (I estimate over 15 hours of work).

Personally I enjoy this part of the build, although towards the end

it did start to drag and I just wanted to get it done so I could

start the paintwork. I had no particular difficulties, although

getting some parts in position was fiddly. Resicast supply the parts

for a full lifting jib and (for a change) a nice diagram complete

with dimensions, to show the positioning of parts. As I’m building

an ARV in the process of towing a Panzer I didn’t build the jib up,

but rather, fitted the parts in their stowed positions. Plastic rod

and resin parts are supplied for this. One part of the kit I

replaced was the cord supplied to represent the tow cables. The real

thing would have been heavy-duty wire, woven to make a cable. The

vehicle in my photo had one cable draped over the front end. I

always feel that cord is to soft and floppy to use for this and

hangs all wrong on the vehicle, so I replaced one of them with

copper cable from Karaya. This gave a much more authentic looking

stiffness to the cable. Other cables are wrapped around hooks on the

hull in a large loop and the supplied cord was fine to represent

this. The kit’s resin end pieces were used, as they were slightly

sharper detailed than the Karaya items.

Due to the fact that I am following a photo of an actual ARV in this

build I had to make a couple of parts not supplied in the kit. The

kit does not have any track guards supplied with it, (The vast

majority of Shermans in the field had their track guards or “sand

shields” removed) but the ARV in the Photo has a full front guard

fitted on the right hand side. I considered leaving it off, but then

decided it could be easily built from Scratch. I didn’t have any

Scratch to hand so I used an empty Cider can instead. I find the

metal used on drinks cans is ideal for building little bits and

pieces of sheet metal, such as track guards, turret bins and the

like. It cuts easily and bends to shape with no problem. Try as I

might I couldn’t find a plan drawing of a Sherman with it’s Guards

fitted, so I studied what photos I could find and made a best guess

at the dimensions. Once made up and placed on the Model it looked

just about right and I was happy with it. I placed a piece of

Verlinden stowage on top of the fender, blended to the shape with

Squadron putty along the bottom.

At the back of the ARV is a box

with a telephone, to allow a crewmember at the rear of the Vehicle

to communicate directions to the driver. The kit supplied one of

these in the closed position. I wanted mine open, with a crewmember

talking to the driver, so I quickly made one up using more metal

from the can and a little plastic card. Finally with all PE fixings

attached a little Squadron putty diluted in Liquid Polly was used to

blend them to the hull. (This gives off strong fumes and good

ventilation is essential) You could also use Mr Surfacer for this

task, but I had none to hand.

The last part of the build process was to check over the model for

glue smears and any other areas that needed clean up before priming.

With every thing fitted the model

was literally bristling with surface features and looked pretty good

to me. Just wait until I get some painting and weathering done! That

will come in the second part of the article, which will concentrate

on painting, weathering and all the finishing touches and details

applied to this model.

This kit is quite a complicated affair and may seem intimidating if

you have never built in resin and PE before. I certainly wouldn’t

recommend it as a first resin project, but chose it for this

article, as it enables me to show most of the techniques and tools

required for a resin kit. Most companies do smaller, easier

subjects, such as armoured cars, which make ideal first tries at

resin. My first resin kit was a Humber scout car, from Accurate

Armour; it’s a nice little kit with fairly good detail and has resin

and PE parts. I would recommend that type of kit as a starting

point. Then once you have the feel of resin models pick something

more challenging.

I bought this kit from Panther models in the UK, through their e-bay

shop. I have been buying from them for about a year now and find

them totally reliable. The model cost £76.99, which is a lot of

money, but this is a lot of model with fabulous detail and no need

for any after market parts. You pay your money and make your choice.

That’s what I did and I’m satisfied with what I got!

Part 2, on finishing, will follow on in the near future.

Click the thumbnails below to view additional images:

Model, Text and Images by Paul

Chatfield

Page Created 15 September, 2006

Page Last Updated

15 September, 2006

|